Kondex was the first to bring laser cladding wear protection technology to HDD tooling in 2019, and has delivered this innovation to multiple markets since 2010. As the "OG LC" laser cladding expert, Kondex utilizes more than a decade of learning the best use applications for the numerous cladding materials and how to pair the technology with manufacturing processes to maximize effectiveness. Competitors brought various knock-off cladding options to market in 2025, but only Kondex-patented tooling offers the longest-possible wear protection to drillers.

What is Laser Cladding?

Laser cladding is an additive manufacturing process that uses a laser to metallurgically bond tungsten carbide to a product’s base material. A laser creates a shallow melt pool of the base metal, while carbide powder is simultaneously introduced into the melt pool to infuse the carbide powder as part of the base metal. This has several advantages:

- Improved impact and wear resistant properties

- Greater carbide distribution

- Longer-retained leading edge

- 2–4 times longer life

Driving Innovation

Kondex Drill Defender™ HDD bits were recognized at the 2021 No-Dig Show as a finalist of the NASTT Abbott Innovative Product Award. As one of only four finalists in the new installation category, Kondex stands out as a company that uses new technologies to drive innovation and bring value to end users.

Kondex Drill Defender™ HDD bits were recognized at the 2021 No-Dig Show as a finalist of the NASTT Abbott Innovative Product Award. As one of only four finalists in the new installation category, Kondex stands out as a company that uses new technologies to drive innovation and bring value to end users.

"What sets our products apart from alternatives on the market is our wear prevention. Our patent-pending laser cladding additive exceeds the limits of hard face welding traditionally used in this market. Not only is laser cladding a more durable and carbide-dense protection, but the application method utilized allows us to add laser cladding to product areas that otherwise could not be protected," commented Kondex VP of Sales John Wagner. "Our goal with laser cladding is to greatly reduce how quickly a product wears by shielding the base material. As a product wears, its performance also degrades. So, the longer we can maintain near net shape, the longer our products will perform at optimal levels. This is a tremendous value in underground drilling, as it reduces the amount of down time otherwise needed to replace worn parts."

Laser Cladding vs. Hard Face Welding

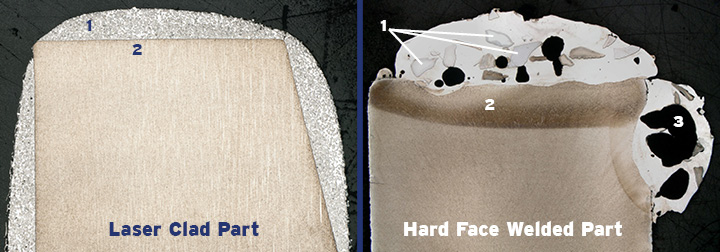

Hard face welding is common to horizontal directional drilling, but just like any industry, technology advances lead to improved products and performance. The latest and leading wear prevention technology is laser cladding, and Kondex is bringing its patent-pending designs and processes to HDD! Our manufacturing processes rely heavily on both surface and microstructure analysis of our products and those we compete against. Below you can see the differences in tungsten carbide density and distribution, heat affected zone, and imperfections — all of which point to the Kondex Drill Defender bit as superior! This deep look at the materials is then proven through longer in-field use and retained steering and carving.

1. Carbide Size and Distribution

The laser clad part includes a high density of tungsten carbides. While these are smaller sized carbides than those on the hard face welded part, the high density and even distribution of carbides on the Kondex bit delivers a greater volume of wear protection. Whereas, the hard face welded part has a larger volume of filler material than carbides for a significantly lower amount of total wear protection.

2. Heat Affected Zone

Large heat affected zones are produced from all hard face welding, which results in very inconsistent hardness values, leaves the product susceptible to cracking and breakage, and accelerates wear once the hard facing is gone. Conversely, our laser cladding and heat treating process leaves no heat affected zone on the Kondex Drill Defender bit. This ensures consistent hardness values, strength, and impact resistance.

3. Voids

Hard face welded parts are at risk for large voids, or empty cavities, due to the imprecise application process. Once these air pockets are revealed from standard wear, the surrounding filler material and carbides are often lost as there's little to nothing securing them to the base part.